Content

Introduction

The construction industry is one of the most dynamic sectors, making it prone to change and disruption. Among many challenges the industry faces, budgeting remains difficult to control as it often shifts throughout the project timeline. While owners and managers may set initial estimates, over 85% of construction projects exceed their budgets, with an average overrun of 28%. A significant contributor to these overruns is workforce inefficiency, driven by the lack of effective management and proper utilization of on-site workers, which leads to low productivity and increased labor costs. According to McKinsey, boosting construction productivity in construction could save up to $1.63 trillion in annual savings. These inefficiencies highlight the urgent need for a solution to drive performance and cost control on-site.

True Cost of Inefficiencies

What is really driving up the cost of inefficiencies in construction sites? While many factors may play a role, main contributors still include project delays, financial penalties and overhead costs, and safety risks and compensation. These issues continue to cause delays, budget overruns, and operational setbacks.

1.Project Delays

One of the most immediate and visible effects of workforce inefficiency is project delay. Late arrivals, idle time, time theft, and lack of accountability can move schedules up. Without proper coordination and oversight, even small issues compound into large disruptions. Statistics show that over 75% of projects are delayed by over 10% of their original timeline, adding weeks or even months of extra labor and equipment costs.

2. Financial Penalties and Overhead Costs

Time is money in construction. Inefficient labor management often leads to extended work hours, overtime pay, and budget overruns. Furthermore, missing project deadlines can trigger penalties defined in contractual agreements. These overhead costs not only increase project budgets and lower profits but also weaken the company’s brand image.

3.Safety Risks and Compensation

When teams operate without clear oversight or under stressful, disorganized conditions, the risk of accidents significantly increases. Slips, falls, and equipment mishandling are often the result of poor coordination and worker fatigue. In fact, 11% of budget overruns are caused by field productivity issues, often related to safety incidents. These incidents not only endanger lives but also lead to costly insurance claims, legal action, and worker compensation payouts, increasing the operational budget burden on the project.

Root Cause of Inefficiencies

Construction inefficiencies are caused by a lack of real-time management and manual workforce tracking. Without real-time data, managers have limited visibility, slow decision-making, and reduced accuracy. However, many sites still depend on manual tracking methods, which are time-consuming, prone to errors, and lack the visibility offered by digital workforce management systems.

Other than that, inefficiency could also be caused by miscommunications and inadequate supervision of safety equipment and hazardous areas. Poor communication between on-site teams and management often leads to misalignment, duplicated work, and project delays. Additionally, inadequate safety supervision increases the risk of injuries and large-scale site shutdowns, further disrupting construction progress and operational efficiency.

How MytePro Workforce Management System Can Help

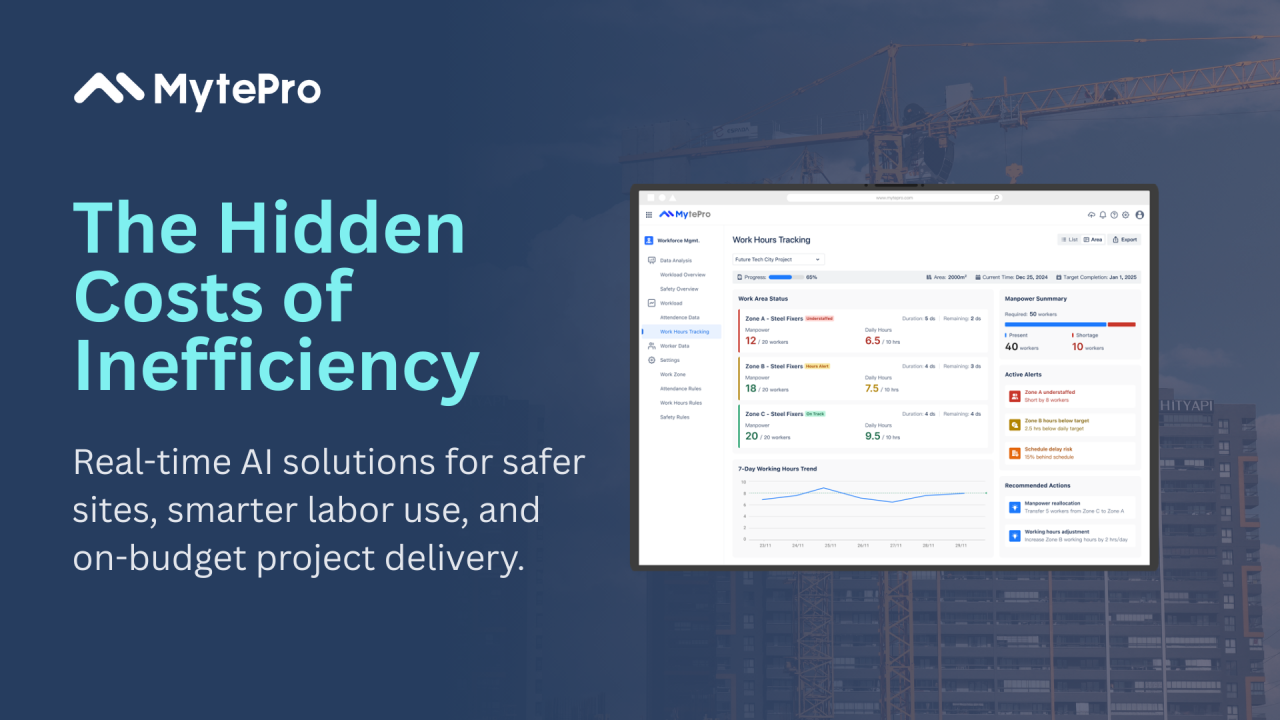

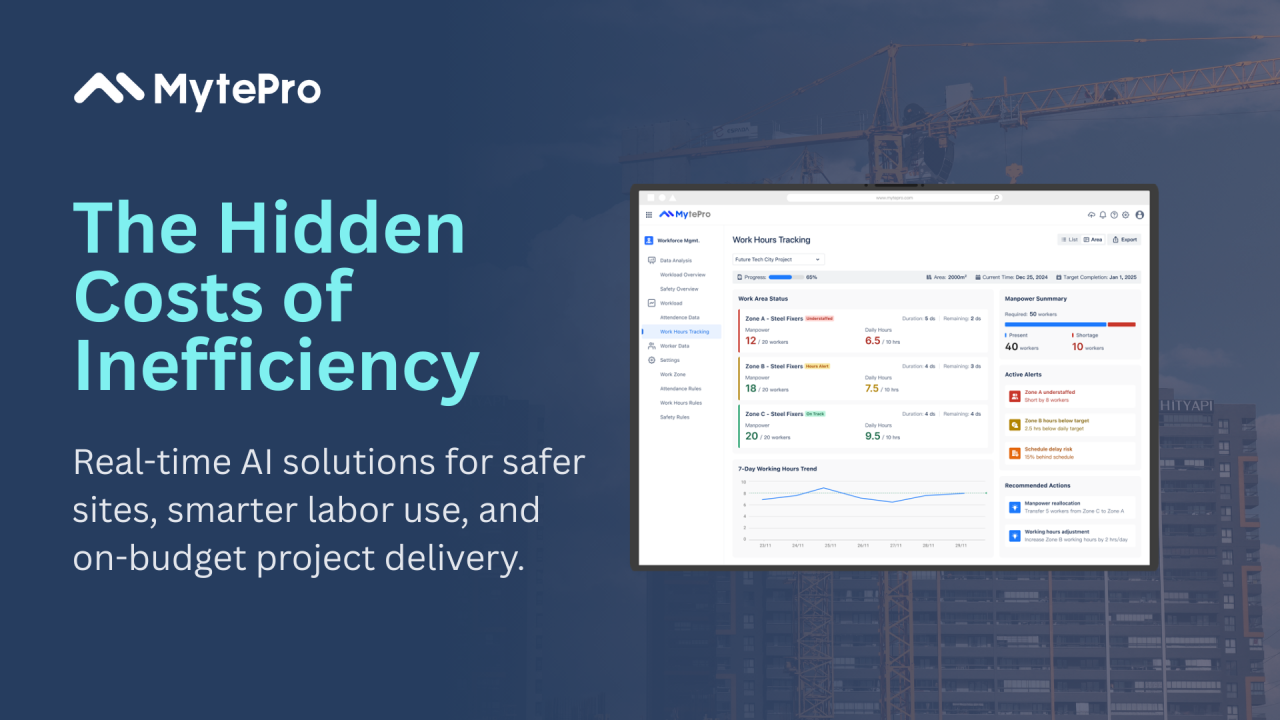

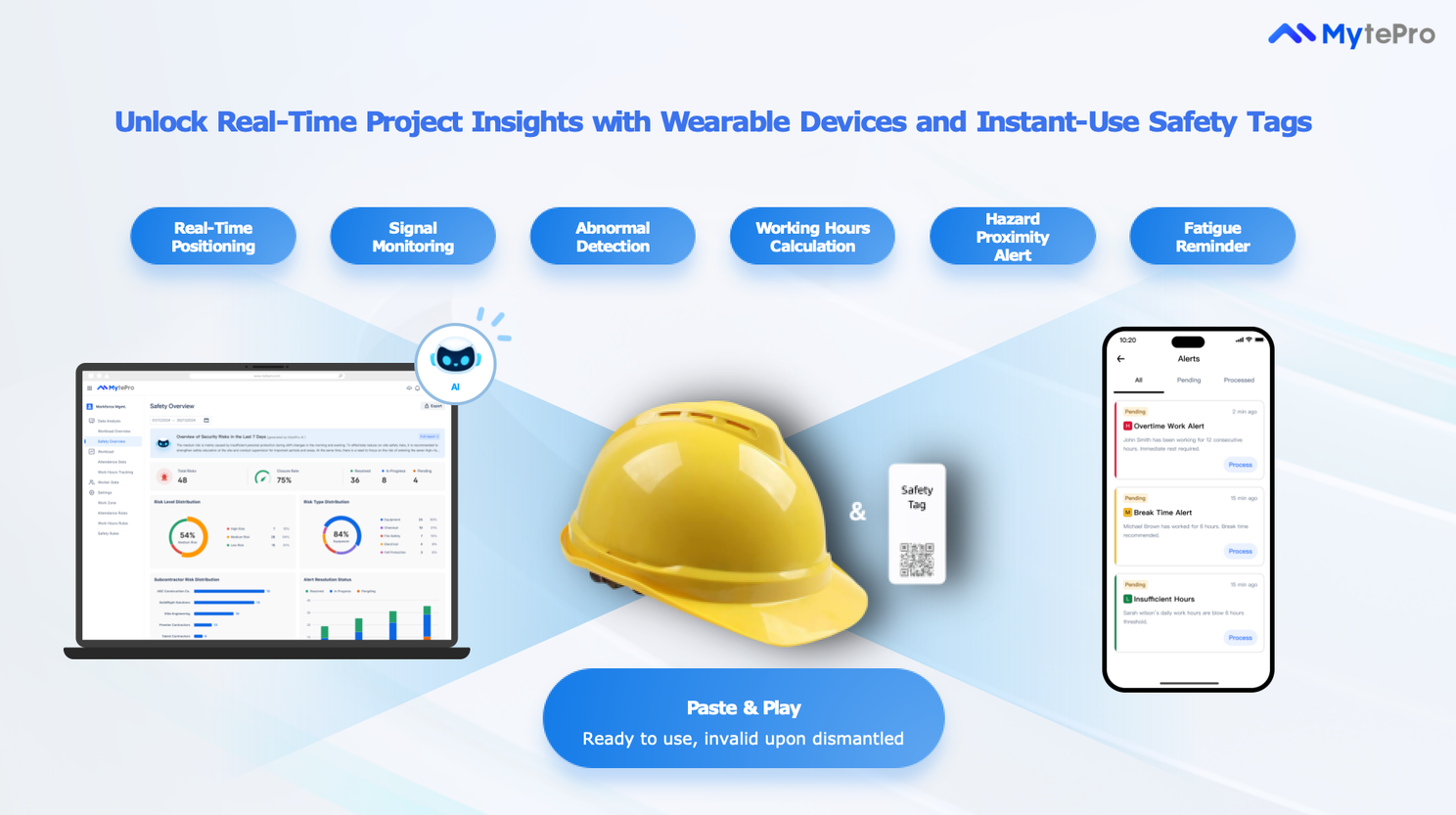

To address the issues mentioned above, MytePro offers smart construction solutions through AI and IoT, focusing on two main areas: improving work hour efficiency and enhancing safety on construction sites. Its real-time monitoring and automated workforce tracking directly solve challenges like poor visibility, manual workforce management, and communication problems. This helps streamline operations and reduce wasted time. Moreover, its smart alert system and geofencing features offer solutions to safety problems traditional construction sites experience, enabling quicker responses and stronger compliance with safety protocols.

1.AI + Real-Time Monitoring

MytePro’s workforce management system allows managers to monitor worker activity and movement across zones in real time. This enables better planning, attendance tracking, and immediate response to inefficiencies or unauthorized behavior on-site.

2. AI + Automatic Warning

The system issues automated alerts when safety thresholds are breached, creating a geofence. When workers enters restricted areas or show signs of fatigue, an alert will sound and managers or the person in charge will be notified. This adds another layer of safety to help prevent incidents before they occur.

3. AI + Safety Assurance

MytePro also ensures compliance through features like helmet detection, rest time monitoring, and real-time zone checks. These tools show a commitment to safety standards and give stakeholders confidence that risks are being managed systematically.

4.AI + Production Efficiencies

With collected data and AI to analyze, MytePro provides insight into worker productivity, time spent per task, and resource allocation. This allows companies to optimize scheduling, reduce downtime, and make data-driven decisions to improve overall efficiency.

Conclusion

Construction inefficiency isn’t only a temporary setback; it presents real financial, operational, and human risk when not handled quickly and correctly. Project delays, legal action, and failure to maintain safety can significantly increase the operational budget. MytePro offers a comprehensive AI-driven solution that addresses these issues by combining real-time visibility, smart alerts, and safety compliance. As the construction industry continues to modernize, tools like MytePro are not just helpful, but they have become an essential tool to building a safer, smarter, and more efficient future

Ready for More Good Reads?